Product Introduction:

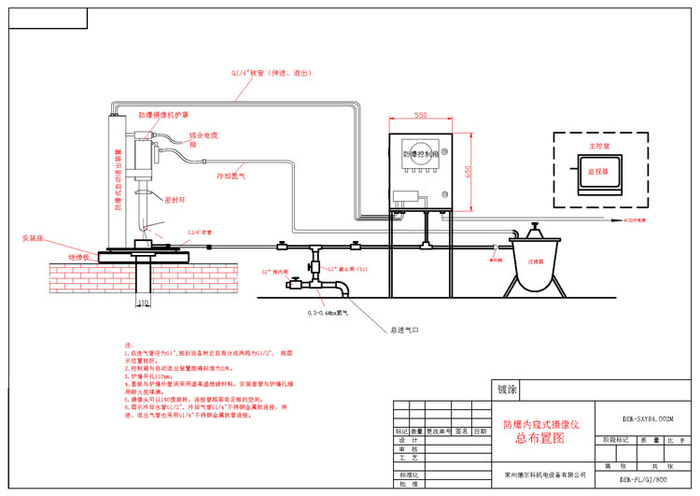

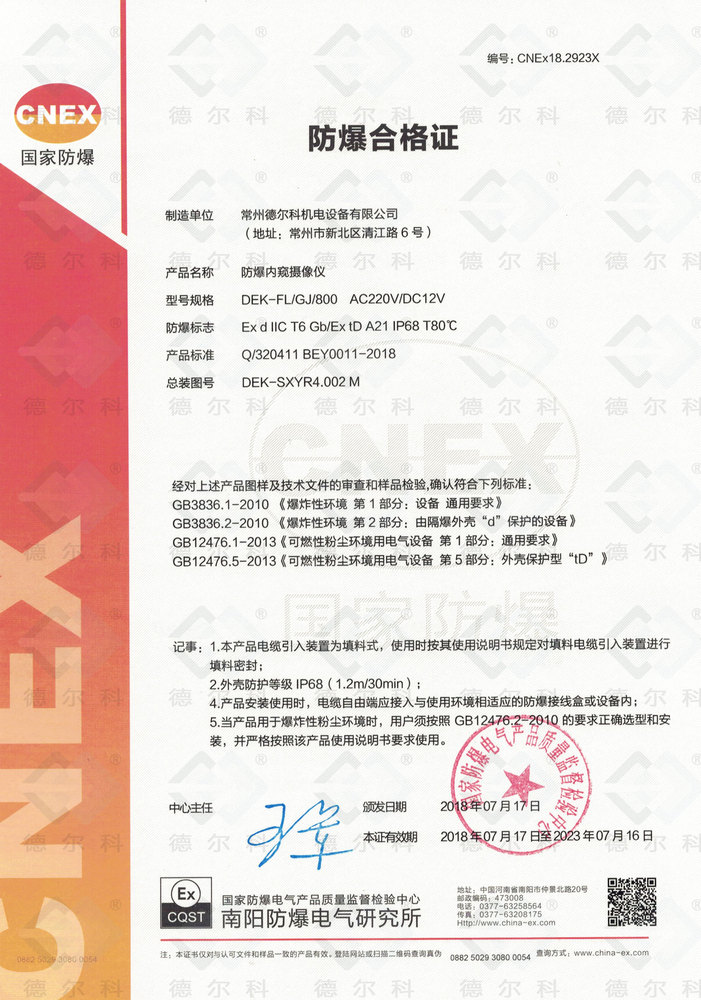

DEK-FL/GL/800 (Ex) explosion-proof endoscope high-temperature camera (hereinafter referred to as "camera"). This product is strictly designed and manufactured in accordance with GB3836.1-2010 Explosive Atmospheres Part 1: General Requirements, GB3836.2-2010 Explosive Atmospheres Part 2: Equipment Protected by Explosion proof Enclosures "d", and GB12476-2000 standards. The camera is mainly applicable to industrial heating furnace, power plant combustion furnace, garbage combustion furnace and steel plant power furnace in the petrochemical industry. For oil, coal and gas furnaces, the camera lens can be directly inserted into the furnace, and the working state of the flame in the furnace can be continuously and real-time monitored in the central control room, so that the combustion nozzle and other objects in the furnace can be clearly observed. For the poor atomization of the nozzle in the furnace, the oil leakage causes unsmooth flame spraying, the flame becomes smaller, and the poor air distribution of the nozzle causes the flame to be too long, resulting in pipe licking phenomenon. The furnace tube deformation in the furnace, sintering and pipe bursting accidents can be monitored in real time and handled in a timely manner to prevent accidents in the furnace, ensure the reliability of the economic operation of the boiler furnace, and also facilitate the realization of centralization Automation of scheduling and production process. The system adopts PLC programmable control and has the function of automatic shutdown and over temperature exit protection.

Structural type: integrated structure with no external connecting wires

Explosion proof form: Exd Ⅱ CT6 Gb, DIPA21 TA, T6

Protection level: IP68 (2m/2h)

Operating temperature (℃): -40~60 ℃

Inlet: 1 G3/4 "explosion-proof inlet

Material: 1Cr18Ni9Ti (304)

Rotation angle (°): 360

Rotation speed (°/s): 20

Motor: High torque permanent magnet DC motor combined with high-precision planetary gear reducer

Transmission structure: full gear structure

Weight (Kg): 100

Control interface: switch quantity

Voltage (V): AC220V, 50/60Hz ± 10%

Current (A):<1

Image system performance indicators

Scanning method: PAL system 625 rows/50 fields 2:1 interlaced

Video output: 1Vp-p synchronous negative polarity 75 ohms

Signal to noise ratio: not less than 42dB

Brightness discrimination level ≥ 8

Color CCD horizontal resolution: 2 million pixels

Turning angle: 60 degrees

Field of view angle: 85 degrees (diagonal)

Power consumption: 60W

Travel: 200-1000mm

camera

Camera model: DS-2CD5223

Minimum illumination: 0.001LUX, F0.75

Clarity: 2 million pixels

Signal to noise ratio: 50dB

Focus adjustment: manual

Aperture adjustment: automatic

Shell material: Metal

Pinhole lens

Focal length: 3.5mm

Relative aperture: 1:3.5

Aperture control range: F3.5-F360

Field of view angle:=Diagonal direction: 85 °; Horizontal direction: 72.5 °; Vertical direction: 57.6 °

Turning angle: 60 °

Connection method: CS seat

External dimensions: φ 25X825mm/960mm/1080mm

Automatic exit function

When the temperature inside the probe housing exceeds the set value (≥ 55 ℃)

When the compressed air pressure is lower than the specified value (≤ 0.3Mpa)

When there is a power outage (USP power supply needs to be set)